5 Ton Hoist: A Comprehensive Guide

Are you in the market for a robust and reliable lifting solution? Look no further than the 5 ton hoist. This versatile piece of equipment is designed to handle heavy loads with precision and ease. In this detailed guide, we will explore the various aspects of a 5 ton hoist, including its features, applications, and maintenance tips.

Understanding the Basics

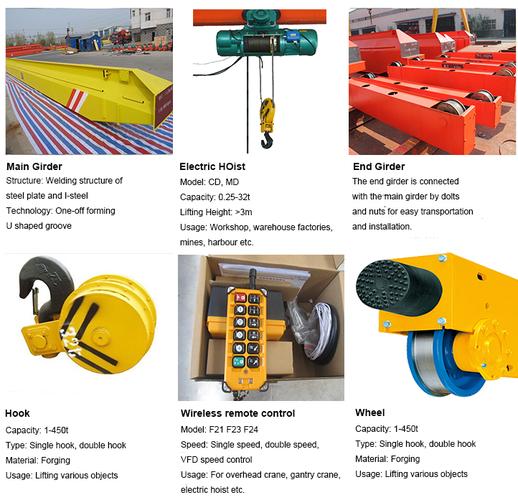

The 5 ton hoist is a type of lifting equipment that can handle loads up to 5 metric tons (5,000 kilograms). It is commonly used in industrial settings, construction sites, and warehouses. The hoist operates using a lifting mechanism, which can be either chain-driven or wire rope-driven, depending on the model.

One of the key features of a 5 ton hoist is its sturdy construction. These hoists are typically made from high-quality materials such as steel, ensuring durability and longevity. They are designed to withstand harsh working conditions and heavy loads, making them an ideal choice for demanding applications.

Types of 5 Ton Hoists

There are several types of 5 ton hoists available on the market, each with its own unique features and applications. Here are some of the most common types:

-

Chain Hoists: These hoists use chains to lift loads. They are suitable for applications where the load is not too heavy and the lifting speed is not critical.

-

Wire Rope Hoists: These hoists use wire ropes for lifting, making them ideal for heavy-duty applications. They offer smoother operation and higher lifting speeds compared to chain hoists.

-

Electric Hoists: These hoists are powered by electricity and are suitable for continuous operation. They come in various configurations, including single-grip, double-grip, and trolley-mounted designs.

-

Manual Hoists: These hoists are operated manually and are suitable for lighter loads and shorter lifting distances. They are often used in maintenance and repair work.

Applications of 5 Ton Hoists

5 ton hoists are versatile pieces of equipment that can be used in a wide range of applications. Here are some of the most common uses:

-

Construction: 5 ton hoists are commonly used in construction projects for lifting materials, equipment, and workers to higher levels.

-

Manufacturing: These hoists are used in manufacturing facilities for lifting heavy components, machinery, and raw materials.

-

Warehouse: 5 ton hoists are ideal for handling heavy loads in warehouses, such as lifting and moving pallets and crates.

-

Marine: These hoists are used in shipyards and ports for lifting cargo, equipment, and personnel.

Choosing the Right 5 Ton Hoist

When selecting a 5 ton hoist, it is important to consider several factors to ensure that you choose the right equipment for your needs. Here are some key considerations:

-

Loading Capacity: Make sure the hoist can handle the maximum load you need to lift.

-

Lifting Height: Choose a hoist with a lifting height that meets your requirements.

-

Control System: Select a hoist with a control system that is easy to use and meets your operational needs.

-

Power Source: Decide whether you need an electric or manual hoist, based on your power supply and operational requirements.

-

Environment: Consider the working environment, such as temperature, humidity, and dust levels, to ensure the hoist is suitable for the conditions.

Maintenance and Safety

Proper maintenance and safety measures are crucial for ensuring the longevity and reliability of a 5 ton hoist. Here are some tips to help you maintain your hoist:

-

Regular Inspection: Conduct regular inspections of the hoist to identify any signs of wear and tear or damage.

-

Lubrication: Apply lubrication to moving parts to ensure smooth operation and reduce wear and tear.

-

Training: Ensure that all operators are properly trained on how to safely operate the hoist.

-

Compliance: Make sure the hoist meets all relevant