5 Ton Overhead Hoist: A Comprehensive Guide

When it comes to lifting heavy loads in industrial settings, a 5 ton overhead hoist is an essential piece of equipment. This guide will delve into the various aspects of a 5 ton overhead hoist, including its design, applications, benefits, and maintenance. Whether you are a business owner, engineer, or just curious about these powerful lifting devices, this article will provide you with a detailed understanding of what a 5 ton overhead hoist is all about.

Design and Construction

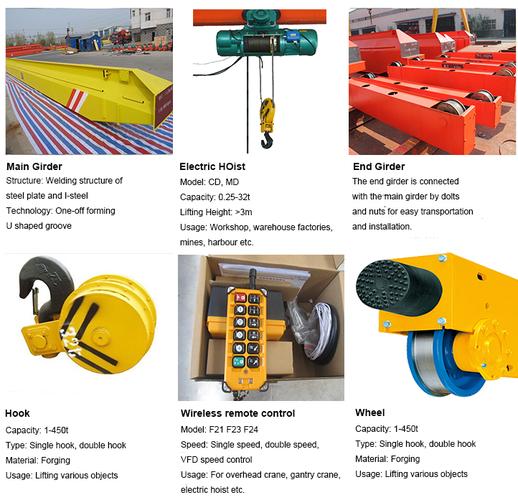

The design of a 5 ton overhead hoist is focused on providing maximum strength and durability. These hoists are typically constructed using high-quality steel, which ensures they can withstand the rigors of heavy-duty lifting. The frame of the hoist is designed to be robust, with reinforced corners and joints to prevent any structural damage.

One of the key components of a 5 ton overhead hoist is the hoist drum. This drum is where the lifting cable is wound, and it is designed to accommodate the weight of the load being lifted. The drum is usually made of steel and features a sturdy construction to ensure it can handle the tension and stress of lifting a 5-ton load.

Another important aspect of the design is the hoist’s lifting mechanism. This mechanism is responsible for raising and lowering the load, and it is typically powered by an electric motor. The motor is designed to provide the necessary torque and power to lift the load smoothly and efficiently.

Applications

5 ton overhead hoists are widely used in various industries, including manufacturing, construction, and logistics. Here are some common applications of these hoists:

-

Manufacturing: In manufacturing facilities, 5 ton overhead hoists are used to lift and move heavy machinery, components, and raw materials. They are particularly useful in assembly lines where precise positioning and movement of parts are required.

-

Construction: In the construction industry, these hoists are used to lift materials and equipment to higher levels, such as in the construction of skyscrapers or bridges. They are also used for lifting workers in confined spaces, such as in the repair of overhead structures.

-

Logistics: In warehouses and distribution centers, 5 ton overhead hoists are used to move heavy loads, such as pallets and containers, from one location to another. They are an essential tool for streamlining the logistics process and improving efficiency.

Benefits

There are several benefits to using a 5 ton overhead hoist in your industrial operations:

-

Increased Efficiency: These hoists can significantly increase the efficiency of your operations by allowing you to lift and move heavy loads quickly and easily.

-

Improved Safety: By automating the lifting process, overhead hoists reduce the risk of accidents and injuries associated with manual lifting.

-

Reduced Labor Costs: Overhead hoists can reduce the need for manual labor, which can lead to lower labor costs in the long run.

-

Customization: Many overhead hoists are available in various configurations and lifting capacities, allowing you to choose the one that best suits your specific needs.

Maintenance

Proper maintenance is crucial for ensuring the longevity and performance of your 5 ton overhead hoist. Here are some key maintenance tips:

-

Regular Inspections: Conduct regular inspections of the hoist to check for any signs of wear and tear, such as loose bolts, damaged cables, or worn-out gears.

-

Lubrication: Keep all moving parts well-lubricated to ensure smooth operation and reduce wear and tear.

-

Replacement Parts: Replace any worn-out or damaged parts as soon as possible to prevent further damage and ensure the safety of your equipment.

-

Training: Ensure that all operators are properly trained on how to use the hoist safely and efficiently.

Comparison with Other Lifting Equipment

When considering a lifting solution for your industrial operations, it’s important to compare different types of equipment, such as cranes, forklifts, and overhead hoists. Here’s a brief comparison of a 5 ton overhead hoist with these alternatives:

| Equipment

Website: https://j4miejohnston.com You May Have like |

|---|