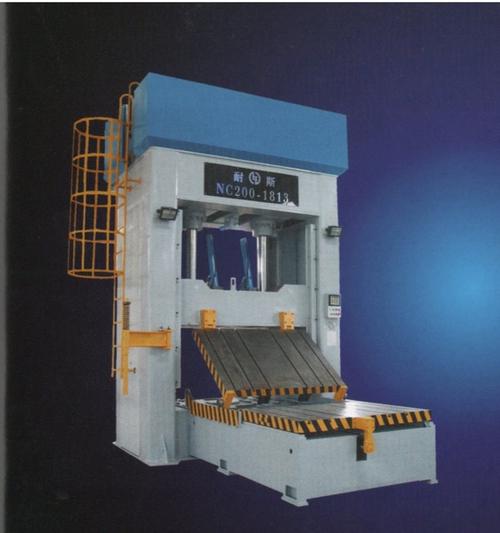

120 Ton Press: A Comprehensive Guide

Are you in the market for a powerful and versatile machine? Look no further than the 120 ton press. This heavy-duty equipment is designed to handle a wide range of tasks, from metalworking to forging. In this article, we will delve into the details of the 120 ton press, exploring its features, benefits, and applications. Whether you are a professional or a hobbyist, this guide will provide you with all the information you need to make an informed decision.

Understanding the 120 Ton Press

The 120 ton press is a type of mechanical press that exerts a force of 120 tons on its workpiece. This force is generated by a hydraulic or mechanical system, depending on the model. The press is commonly used in various industries, including automotive, aerospace, and manufacturing, for tasks such as bending, forming, and stamping.

One of the key features of the 120 ton press is its ability to handle heavy-duty applications. It is capable of working with materials such as steel, aluminum, and brass, making it a versatile tool for a wide range of projects.

Types of 120 Ton Presses

There are several types of 120 ton presses available on the market, each with its own unique features and benefits. Here are some of the most common types:

-

Hydraulic Press: This type of press uses hydraulic fluid to generate force. It is known for its smooth operation and high precision.

-

Mechanical Press: A mechanical press uses a series of gears and levers to generate force. It is often more affordable than a hydraulic press but may require more maintenance.

-

CNC Press: A CNC (Computer Numerical Control) press is equipped with a computerized control system that allows for precise and repeatable operations.

Features of the 120 Ton Press

The 120 ton press is packed with features that make it an excellent choice for a variety of applications. Here are some of the key features to consider:

-

High Force: The 120 ton press can exert a force of 120 tons, making it suitable for heavy-duty tasks.

-

Smooth Operation: Both hydraulic and mechanical presses offer smooth operation, ensuring precise and repeatable results.

-

Large Workspace: The 120 ton press typically features a large workspace, allowing for the handling of large workpieces.

-

Adjustable Die Sets: Many 120 ton presses come with adjustable die sets, which allow for easy customization of the press’s capabilities.

Benefits of Using a 120 Ton Press

Using a 120 ton press offers several benefits, including:

-

Increased Productivity: The 120 ton press can handle heavy-duty tasks quickly and efficiently, increasing productivity in your workshop.

-

Improved Quality: The precision and consistency of the 120 ton press ensure high-quality results, reducing the need for rework.

-

Cost-Effective: While the initial cost of a 120 ton press may be high, the long-term benefits, such as increased productivity and reduced downtime, can make it a cost-effective investment.

Applications of the 120 Ton Press

The 120 ton press is a versatile tool that can be used in various industries and applications. Here are some of the most common uses:

-

Automotive Industry: The 120 ton press is used for tasks such as bending, forming, and stamping metal parts for vehicles.

-

Aerospace Industry: The press is used to produce lightweight, high-strength components for aircraft and spacecraft.

-

Manufacturing Industry: The 120 ton press is used for a wide range of manufacturing processes, including metalworking, forging, and stamping.

Choosing the Right 120 Ton Press

When choosing a 120 ton press, it is important to consider several factors to ensure that you select the right machine for your needs. Here are some key considerations:

-

Application: Determine the specific tasks you will be using the press for, as this will help you choose the right type of press (hydraulic, mechanical, or CNC).