Understanding the 1 Ton Glycol Chiller: A Comprehensive Guide

Are you considering investing in a glycol chiller for your industrial or commercial needs? If so, you’ve come to the right place. In this detailed guide, we’ll delve into the intricacies of a 1 ton glycol chiller, exploring its features, benefits, and how it can enhance your operations. Let’s get started.

What is a Glycol Chiller?

A glycol chiller is a cooling system designed to remove heat from a process or space. Unlike traditional chillers that use water, glycol chillers use a mixture of water and antifreeze, known as glycol, to achieve lower temperatures. This makes them ideal for environments where freezing temperatures are a concern.

Why Choose a 1 Ton Glycol Chiller?

Now that we understand what a glycol chiller is, let’s discuss why a 1 ton model might be the perfect choice for your needs.

1. Efficient Cooling Capacity

A 1 ton glycol chiller can cool up to 1 ton of refrigerant, which is equivalent to 12,000 BTUs (British Thermal Units). This makes it suitable for a wide range of applications, from small-scale laboratories to large industrial processes.

2. Energy Efficiency

Modern glycol chillers, including the 1 ton model, are designed to be energy-efficient. They use advanced technology to minimize energy consumption, reducing your operational costs in the long run.

3. Compact Design

Despite its cooling capacity, a 1 ton glycol chiller is designed to be compact, making it easy to install in limited spaces. This is particularly beneficial for businesses with limited floor space or those looking to optimize their facilities.

4. Versatility

1 ton glycol chillers can be used in various applications, such as air conditioning, food processing, pharmaceuticals, and more. Their versatility makes them a valuable asset for any business.

Key Features of a 1 Ton Glycol Chiller

Now that we’ve established the benefits of a 1 ton glycol chiller, let’s take a closer look at some of its key features.

| Feature | Description |

|---|---|

| Refrigerant Type | High-efficiency refrigerant designed for optimal cooling performance |

| Compressor | High-quality scroll or reciprocating compressor for reliable operation |

| Condenser | Efficient condenser design for quick heat transfer |

| Evaporator | High-performance evaporator for effective heat absorption |

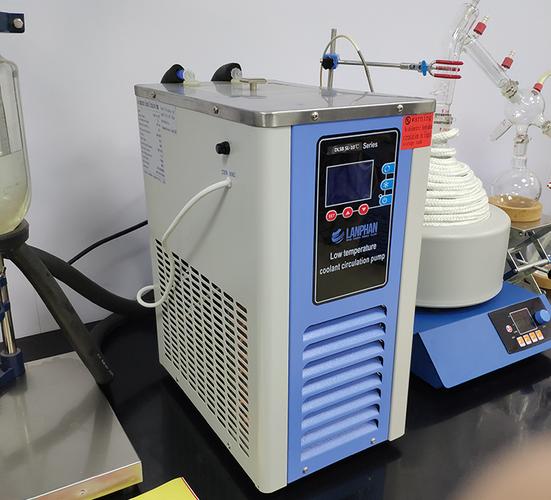

| Control Panel | User-friendly control panel with digital display for easy operation |

| Sound Insulation | Advanced sound insulation for quiet operation |

How to Install a 1 Ton Glycol Chiller

Installing a 1 ton glycol chiller requires careful planning and execution. Here are some key steps to ensure a successful installation:

- Choose the right location: Ensure the chiller is placed in a well-ventilated area with adequate space for maintenance and operation.

- Prepare the installation site: Clear the area, level the ground, and ensure proper electrical connections.

- Assemble the chiller: Follow the manufacturer’s instructions to assemble the chiller components.

- Connect the glycol system: Install the glycol piping, pump, and filter to ensure proper circulation and temperature control.

- Connect the electrical system: Ensure the electrical connections are secure and meet safety standards.

- Start the chiller: Follow the manufacturer’s instructions to start the chiller and monitor its operation.

Maintenance and Troubleshooting

Regular maintenance is crucial for the optimal performance and longevity of your 1 ton glycol chiller. Here are some maintenance tips and common troubleshooting