10 Ton Overhead Crane: A Comprehensive Guide

When it comes to heavy-duty lifting equipment, the 10 ton overhead crane stands out as a versatile and robust solution for various industrial applications. Whether you’re working in a manufacturing plant, construction site, or warehouse, understanding the intricacies of a 10 ton overhead crane is crucial for ensuring safe and efficient operations. In this detailed guide, we’ll explore the key aspects of a 10 ton overhead crane, including its design, components, applications, and maintenance.

Design and Structure

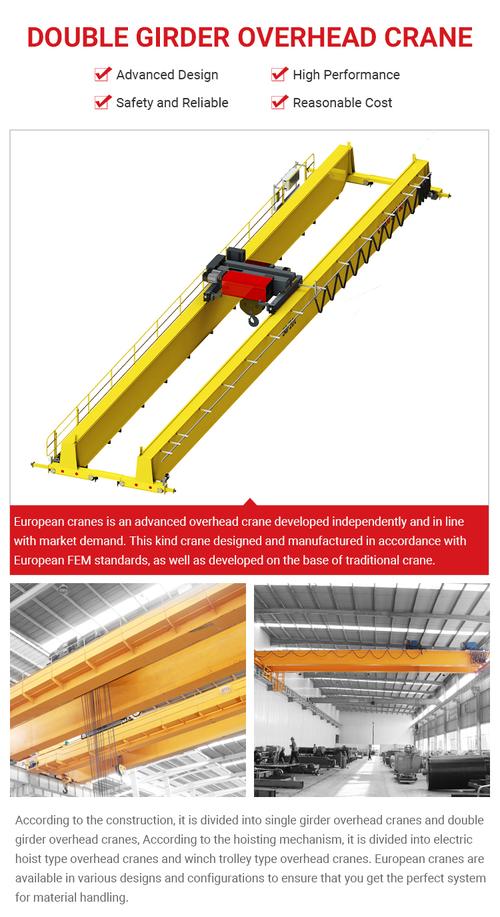

The design of a 10 ton overhead crane is focused on providing maximum strength and stability while minimizing weight. Typically, these cranes are constructed using high-quality steel materials, ensuring durability and longevity. The main components of a 10 ton overhead crane include the bridge, runway, trolley, hoist, and electrical system.

| Component | Description |

|---|---|

| Bridge | The horizontal beam that spans across the runway, supporting the trolley and hoist. |

| Runway | The track system that runs along the walls of the building, providing a path for the crane to move. |

| Trolley | The carriage that moves along the bridge, carrying the hoist and lifting the load. |

| Hoist | The lifting mechanism that raises and lowers the load. |

| Electrical System | The system that powers the crane, including motors, controllers, and wiring. |

Applications

10 ton overhead cranes are widely used in various industries due to their versatility and lifting capacity. Some common applications include:

- Manufacturing: Used for lifting heavy components, machinery, and raw materials in factories.

- Construction: Essential for lifting materials and equipment during the construction of buildings, bridges, and other infrastructure projects.

- Warehouse: Ideal for handling large loads and organizing inventory in warehouses and distribution centers.

- Energy Sector: Used for lifting heavy equipment and materials in power plants, refineries, and other energy-related facilities.

Components and Features

Understanding the components and features of a 10 ton overhead crane is essential for ensuring safe and efficient operation. Here are some key components and features to consider:

- Hoist: The hoist is the lifting mechanism that raises and lowers the load. It comes in various types, such as chain hoists, wire rope hoists, and electric hoists.

- Trolley: The trolley moves along the bridge, carrying the hoist and lifting the load. It can be manually operated or motorized, depending on the crane’s design.

- Bridge: The bridge is the horizontal beam that spans across the runway, supporting the trolley and hoist. It can be single girder or double girder, depending on the crane’s capacity and span.

- Runway: The runway is the track system that runs along the walls of the building, providing a path for the crane to move. It must be properly aligned and maintained to ensure smooth operation.

- Electrical System: The electrical system powers the crane, including motors, controllers, and wiring. It must be properly installed and maintained to ensure safe operation.

Maintenance and Safety

Maintaining a 10 ton overhead crane is crucial for ensuring safe and efficient operation. Here are some key maintenance and safety considerations:

- Regular Inspections: Conduct regular inspections of the crane’s components, including the bridge, runway, trolley, hoist, and electrical system. Look for signs of wear, damage, or misalignment.

- Preventive Maintenance: Perform preventive maintenance tasks, such as lubricating moving parts, checking wiring, and inspecting the crane’s structural integrity.

- Operator Training: Ensure that all operators are properly trained on how to safely operate the crane. This includes understanding the crane’s controls, limitations, and safety