Press 40 Ton: A Comprehensive Guide

Are you looking to invest in a heavy-duty press machine that can handle up to 40 tons of force? If so, you’ve come to the right place. In this article, we will delve into the various aspects of a 40-ton press, including its applications, types, specifications, and benefits. Whether you are a manufacturer, engineer, or simply curious about these powerful machines, this guide will provide you with all the information you need.

Applications of a 40-Ton Press

A 40-ton press is a versatile piece of equipment that can be used in various industries. Some of the most common applications include:

- Automotive manufacturing: For the production of car parts, such as engine blocks and cylinder heads.

- Machine tool manufacturing: For the production of complex metal components used in machine tools.

- Forging: For the production of forgings, such as gears and shafts.

- Stamping: For the production of metal stampings, such as automotive body panels.

Types of 40-Ton Presses

There are several types of 40-ton presses available in the market, each with its unique features and benefits. Here are some of the most common types:

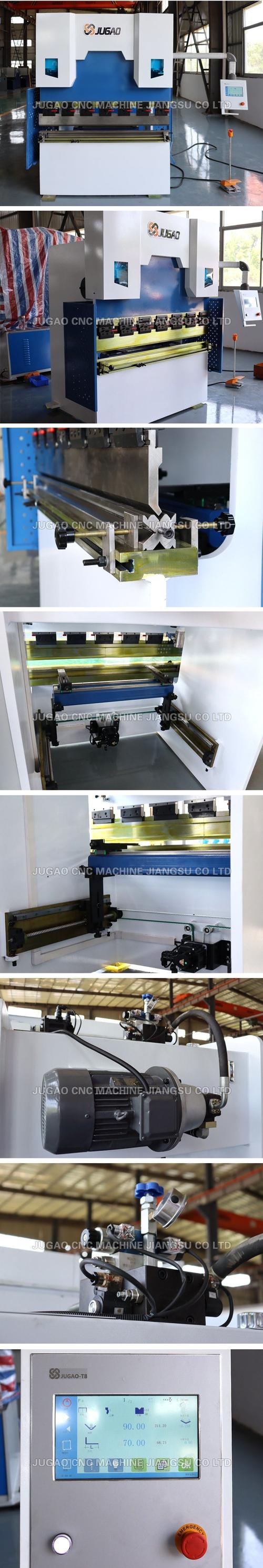

- Hydraulic Press: These presses use hydraulic fluid to generate the required force. They are known for their smooth operation and high precision.

- Mechanical Press: These presses use mechanical linkages to generate force. They are more robust and can handle heavier loads than hydraulic presses.

- Electrical Press: These presses use electric motors to generate force. They are known for their energy efficiency and low maintenance costs.

Specifications of a 40-Ton Press

When selecting a 40-ton press, it is essential to consider several specifications to ensure that it meets your requirements. Here are some of the key specifications to consider:

- Force: The maximum force that the press can generate, typically measured in tons.

- Stroke Length: The distance the ram can travel vertically, typically measured in millimeters.

- Table Size: The size of the press table, which determines the size of the workpiece that can be processed.

- Speed: The speed at which the ram can travel, typically measured in millimeters per minute.

- Power Source: The type of power source used, such as electric, hydraulic, or mechanical.

Here is a table comparing the specifications of a hydraulic, mechanical, and electrical 40-ton press:

| Specification | Hydraulic Press | Mechanical Press | Electrical Press |

|---|---|---|---|

| Force (tons) | 40 | 40 | 40 |

| Stroke Length (mm) | 200-1000 | 200-1000 | 200-1000 |

| Table Size (mm) | 1000×1000 | 1000×1000 | 1000×1000 |

| Speed (mm/min) | 10-100 | 10-100 | 10-100 |

| Power Source | Hydraulic | Mechanical | Electric |

Benefits of Using a 40-Ton Press

Using a 40-ton press offers several benefits, including:

- Increased Productivity: These presses can handle large volumes of work, leading to increased productivity.

- Improved Quality: The