5000 Ton Press: A Comprehensive Overview

Are you intrigued by the power and precision of heavy-duty machinery? Look no further than the 5000 ton press. This marvel of engineering is not just a piece of equipment; it’s a testament to human ingenuity and the ability to shape the world around us. In this article, we will delve into the various aspects of the 5000 ton press, from its history to its applications, and everything in between.

History of the 5000 Ton Press

The 5000 ton press has a rich history that dates back to the early 20th century. Initially developed for the automotive industry, these presses were used to stamp out metal parts for vehicles. Over the years, their applications have expanded to include aerospace, construction, and even art.

One of the earliest examples of a 5000 ton press was the General Motors Stamping Plant in Flint, Michigan, which was built in the 1920s. This plant was a marvel of its time, and it set the standard for future press designs.

Design and Construction

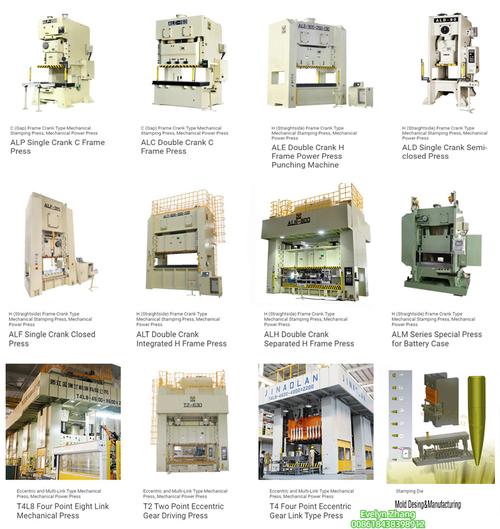

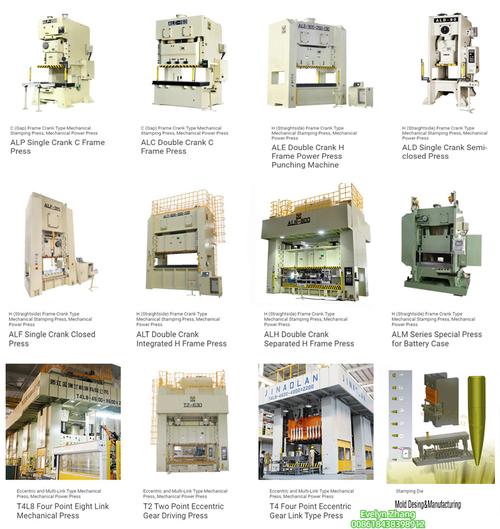

The 5000 ton press is a massive piece of machinery, with some models weighing over 100 tons and standing over 20 feet tall. Its design is both simple and complex, with a focus on strength, precision, and durability.

The press consists of a hydraulic or mechanical system that applies force to a die, which is a mold used to shape the metal. The die is mounted on a ram, which moves up and down, and the force is transmitted through a series of gears and shafts.

One of the key components of the 5000 ton press is the hydraulic system. This system uses hydraulic fluid to generate the force needed to operate the press. The fluid is stored in a reservoir and is pressurized using a pump. The pressure is then used to move the ram and the die.

Applications of the 5000 Ton Press

The 5000 ton press is a versatile piece of equipment that is used in a variety of industries. Here are some of the most common applications:

-

Automotive Industry: The automotive industry is one of the largest users of 5000 ton presses. These presses are used to stamp out parts such as body panels, doors, and hoods.

-

Aerospace Industry: In the aerospace industry, 5000 ton presses are used to form complex metal parts for aircraft. These parts include landing gear, wing ribs, and fuselage sections.

-

Construction Industry: The construction industry uses 5000 ton presses to form large metal structures, such as beams and columns. These structures are then used in the construction of buildings, bridges, and other infrastructure projects.

-

Art and Sculpture: Some artists use 5000 ton presses to create unique sculptures and metalworks. The immense force of the press allows them to shape metal into intricate designs that would be impossible to achieve by hand.

Advantages of the 5000 Ton Press

There are several advantages to using a 5000 ton press:

-

High Precision: The 5000 ton press can produce parts with very tight tolerances, ensuring that they fit together perfectly.

-

High Speed: These presses can operate at high speeds, which increases production rates and reduces costs.

-

Low Labor Costs: The 5000 ton press can automate many of the tasks that would otherwise require manual labor, reducing labor costs.

Challenges of Using the 5000 Ton Press

While the 5000 ton press offers many advantages, there are also some challenges associated with its use:

-

High Initial Cost: The cost of purchasing and installing a 5000 ton press can be quite high.

-

Complex Maintenance: These presses require regular maintenance to ensure they operate safely and efficiently.

-

Space Requirements: The size of a 5000 ton press means that it requires a significant amount of space in a manufacturing facility.

Conclusion

The 5000 ton press is a powerful and versatile piece of machinery that has revolutionized the way we produce metal parts. Its history, design, applications, and advantages make it a valuable asset to any manufacturing facility. While there are challenges associated with its use, the benefits far outweigh