Press 1000 Ton: A Comprehensive Guide

When it comes to heavy-duty machinery, the term “press 1000 ton” often evokes images of immense power and capability. This article delves into the intricacies of such presses, exploring their design, applications, and the industries that rely on them.

Understanding the Basics

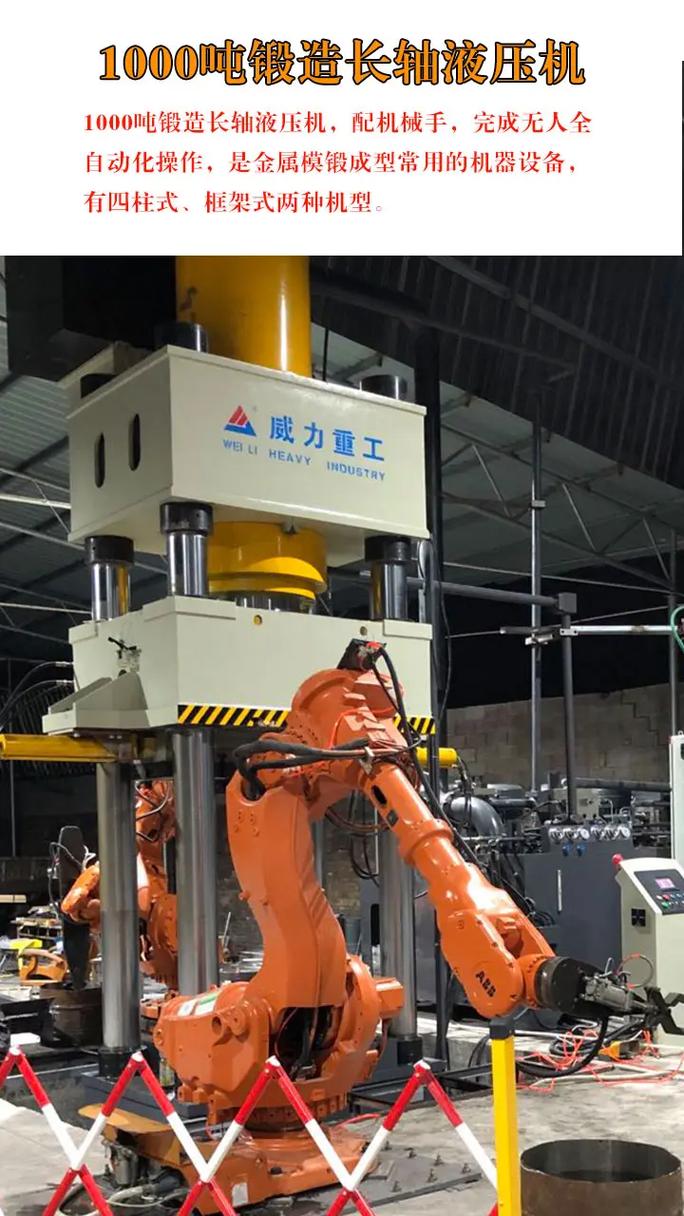

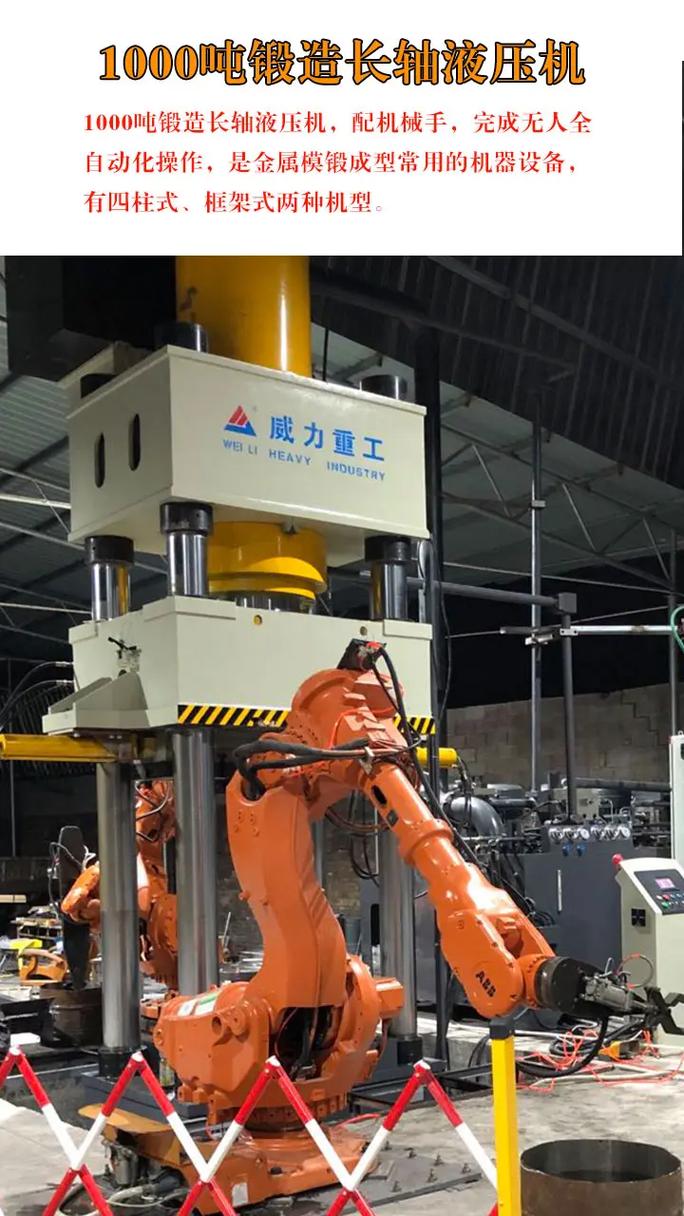

A press 1000 ton refers to a machine that can exert a force of 1000 metric tons. This force is typically used to compress, shape, or form materials such as metal, plastic, or rubber. These presses are essential in various industries, including automotive, aerospace, and construction.

Types of Presses

There are several types of presses that can exert a force of 1000 tons. The most common types include:

| Type | Description |

|---|---|

| Hydraulic Press | Utilizes hydraulic fluid to generate force. They are versatile and can be used for a wide range of applications. |

| Mechanical Press | Operates using mechanical linkages and is often used for high-force, low-speed operations. |

| Electromagnetic Press | Uses electromagnetic fields to generate force. They are highly efficient and can be controlled with precision. |

Applications

Presses with a 1000-ton capacity find applications in numerous industries. Here are some of the most common uses:

-

Automotive Industry: These presses are used to stamp out metal parts, such as body panels and engine components.

-

Aerospace Industry: They are employed to form complex metal parts for aircraft structures.

-

Construction Industry: Presses with this capacity are used to produce precast concrete elements, such as beams and columns.

-

Plastic Industry: They are used to mold large plastic parts for various applications, including furniture and automotive interiors.

Design and Construction

The design and construction of a 1000-ton press are critical to ensure its reliability and efficiency. Here are some key aspects:

-

Frame: The frame is the backbone of the press and must be robust enough to withstand the immense forces exerted.

-

Power Unit: The power unit generates the force required to operate the press. It can be hydraulic, mechanical, or electromagnetic.

-

Control System: The control system allows for precise control of the press’s operation, ensuring safety and efficiency.

-

Workholding: The workholding system securely holds the material being processed, ensuring accurate and repeatable results.

Safety Considerations

Operating a 1000-ton press requires strict adherence to safety protocols. Here are some key safety considerations:

-

Training: Operators must receive proper training on the safe operation of the press.

-

Lockout/Tagout: This procedure ensures that the press is de-energized before maintenance or repair work.

-

Personal Protective Equipment (PPE): Operators must wear appropriate PPE, such as safety glasses, gloves, and hearing protection.

-

Emergency Stop: The press must be equipped with a readily accessible emergency stop button.

Conclusion

Presses with a 1000-ton capacity are essential tools in many industries. Their immense power and versatility make them invaluable for a wide range of applications. By understanding their design, construction, and safety considerations, you can ensure that these presses operate efficiently and safely.