10 Ton Press Machine: A Comprehensive Guide

Are you in the market for a robust and versatile press machine? Look no further than the 10 ton press machine. This powerful tool is designed to handle a wide range of applications, from metalworking to plastic molding. In this article, we will delve into the details of the 10 ton press machine, covering its features, specifications, and benefits.

Understanding the Basics

The 10 ton press machine is a type of mechanical press that exerts a force of 10 tons on the material being worked on. This force is generated by a hydraulic or mechanical system, depending on the model. The machine is commonly used in industries such as metalworking, plastic molding, and forging.

One of the key advantages of the 10 ton press machine is its versatility. It can be used for a variety of tasks, including bending, forming, and cutting. This makes it an essential tool for many manufacturing processes.

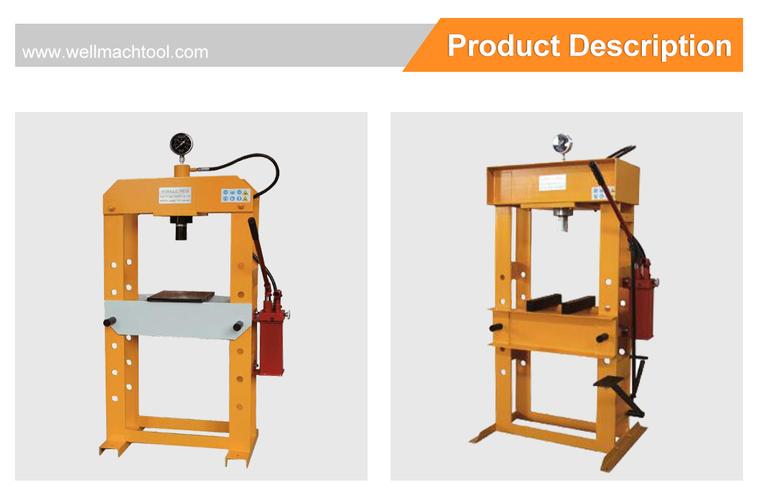

Types of 10 Ton Press Machines

There are several types of 10 ton press machines available, each with its own unique features and applications. Here are some of the most common types:

-

Hydraulic Press: This type of press uses hydraulic fluid to generate the required force. It is ideal for heavy-duty applications and offers smooth and precise operation.

-

Mechanical Press: A mechanical press uses a mechanical system, such as a flywheel, to generate force. It is suitable for lighter-duty applications and is often more cost-effective than hydraulic presses.

-

CNC Press: A CNC (Computer Numerical Control) press combines the precision of a computer-controlled system with the power of a mechanical press. It is ideal for high-volume production and complex parts.

Key Features of a 10 Ton Press Machine

When choosing a 10 ton press machine, there are several key features to consider:

-

Force: The force of the press is one of the most important factors to consider. A 10 ton press machine can exert a force of 10 tons, making it suitable for heavy-duty applications.

-

Stroke Length: The stroke length is the distance the press moves during the pressing cycle. A longer stroke length allows for greater depth of penetration, which is important for certain applications.

-

Speed: The speed of the press is another important factor. A faster press can increase productivity and reduce cycle times.

-

Control System: The control system of the press is crucial for ensuring accurate and repeatable operation. Look for a press with a user-friendly control panel and advanced features such as programmable sequences and safety interlocks.

Specifications of a 10 Ton Press Machine

Here are some typical specifications for a 10 ton press machine:

| Specification | Value |

|---|---|

| Force | 10 tons |

| Stroke Length | 100 mm to 500 mm |

| Speed | 1 to 30 strokes per minute |

| Power Supply | 3-phase, 380V, 50/60 Hz |

| Dimensions | 1500 mm x 800 mm x 1500 mm |

| Weight | 2000 kg |

Benefits of Using a 10 Ton Press Machine

Using a 10 ton press machine offers several benefits, including:

-

Increased Productivity: The high force and speed of the press can significantly increase productivity, allowing for faster production cycles.

-

Improved Quality: The precision and consistency of the press ensure high-quality results, reducing the need for rework and scrap.

-

Cost-Effective: While the initial cost of a 10 ton press machine may be high, the long-term savings in labor and